How to Choose the Right Double Column Machining Center for Large-Part Machining?

- Share

- publisher

- Stitch

- Issue Time

- Dec 8,2025

Summary

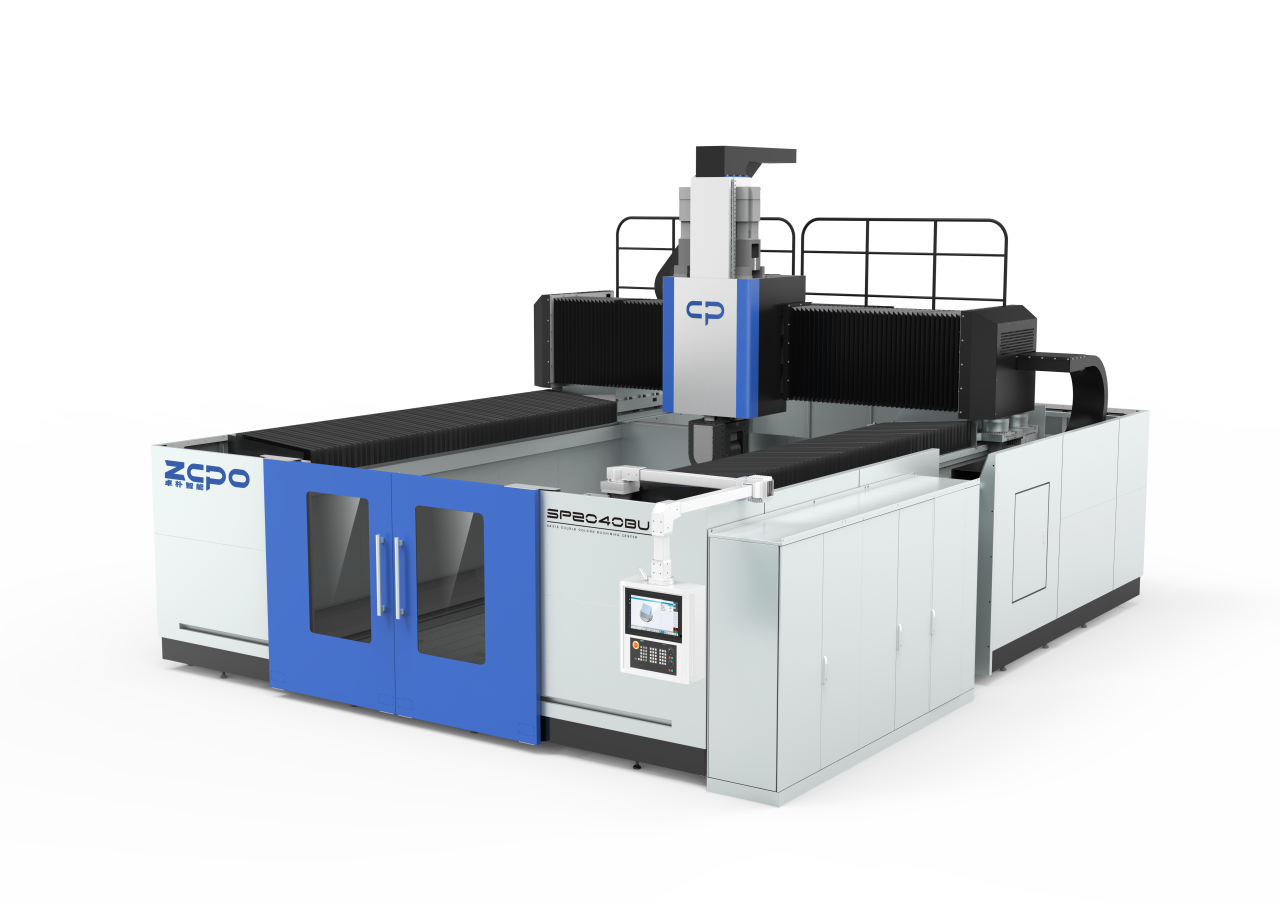

When your production involves extra-large, heavy, and high-precision workpieces, choosing the right machining solution is no longer just about efficiency—it is about long-term accuracy, stability, and investment security. In such cases, a Double Column Machining Center (also commonly known as a gantry machining center) becomes the ideal solution.

What Is a Double column Machining Center?

A Double Column Machining Center is a large-format CNC machine featuring a dual-column structure with a crossbeam forming a rigid portal frame. This design allows the machine to maintain excellent stability when machining oversized and heavy workpieces.

Key characteristics include:

1. Extra-large worktable size and high load capacity

2. Outstanding structural rigidity

3. Long travel accuracy

4. Multi-process capability: milling, drilling, boring, tapping, and contouring

5. Ideal for heavy-duty and large-surface machining

Compared with traditional Vertical Machining Centers (VMCs), double column machines are purpose-built for large-part, high-load, and high-stability machining.

When Do You Need a Double Column Machining Center?

Not every factory needs this type of machine. However, you should seriously consider a double column machining center if any of the following conditions apply to your production.

Large and Heavy Workpieces

If your typical workpieces:

1. Exceed 2–3 meters in length

2. Weigh several tons or more

Then conventional VMCs simply cannot provide sufficient table size or load capacity. A double column machining center ensures safe, stable, and distortion-free machining of such parts.

Typical industries include:

1. Large mold bases

2. Wind power components

3. Shipbuilding structures

4. Rail transit frames

5. Heavy machinery beds

High Precision Required on Large Surfaces

Large components are more sensitive to:

1. Structural deformation

2. Thermal displacement

3. Vibration during cutting

4. Accumulated positioning errors

The symmetrical double-column structure effectively distributes stress and vibration, allowing the machine to maintain long-term geometric accuracy and consistent surface quality.

Heavy Cutting and High Material Removal

If your production mainly involves:

1. Carbon steel

2. Alloy steel

3. Cast iron

4. Titanium or difficult-to-cut materials

Then you need:

1. High spindle torque

2. Strong beam and column rigidity

3. Heavy-duty guideway systems

This is where a double column machining center clearly outperforms standard machines.

One Setup for Multiple Processes

Double column machines allow:

1. Rough machining

2. Semi-finishing

3. Finishing

Drilling and tapping

to be completed in a single setup, which significantly improves:

Machining accuracy

Production efficiency

Batch consistency

Key Factors When Choosing a Double Column Machining Center

Choosing the right machine is not about selecting the largest one—it is about selecting the most suitable configuration for your real production needs. The following factors are critical.

Worktable Size and Load Capacity

Before selection, clearly define:

1. Maximum workpiece length

2. Maximum width

3. Maximum height

4. Maximum weight

Your machine capacity should exceed actual production needs by at least 20–30% to ensure safety, rigidity, and future scalability.

ZOPO CNC offers customized large-table double column solutions to match different industrial requirements.

Machine Structure and Rigidity

Rigidity directly determines:

1. Cutting depth

2. Tool life

3. Surface finish

4. Dimensional stability

High-quality double column machining centers must feature:

1. Thick cast iron columns

2. High-strength crossbeam

3. Optimized rib structure design

4. Precision ground guideway surfa

Spindle Power, Torque, and Speed

Different materials require different spindle configurations:

1. Steel & cast iron → High-torque gearbox spindle

2. Aluminum alloys → High-speed spindle

3. Titanium & heat-resistant alloys → High torque + thermal stability

ZOPO CNC supports multiple spindle solutions to match various cutting conditions.

Guideway System Selection

1. Box guideway: Maximum rigidity for heavy cutting

2. Roller linear guideway: Higher speed and smoother motion

3. For many applications, ZOPO CNC also provides hybrid guideway solutions to balance rigidity and speed.

CNC Control System and Automation

Mainstream CNC systems include:

1. Siemens

2. FANUC

3. Mitsubishi

4. Optional automation solutions:

5. Automatic tool changers

6. Rotary tables

7. Workpiece clamping systems

8. Tool monitoring and probing systems

All these directly affect production efficiency and long-term stability

Typical Industries Using ZOPO CNC Double Column Machining Centers

ZOPO CNC double column machining centers are widely applied in:

1. Large mold and die manufacturing

2. Wind turbine hubs and frames

3. Aerospace structural components

4. Rail transit components

5. Heavy steel fabrication and energy equipment

Why Choose ZOPO CNC for Double Column Machining Solutions?

As a professional CNC machine tool manufacturer, ZOPO CNC focuses on providing reliable, stable, and industry-oriented machining solutions.

Our advantages include:

Customized configurations for different industries

1. Strict manufacturing and assembly quality control

2. Global export and project experience

3. Professional technical support before and after sales

4. Long-term production stability for large-part machining

We are not just a machine supplier—we are your long-term manufacturing partner.

How to Avoid Wrong Investment in Double Column Machines

Before purchasing, always confirm:

1. What is my largest part size?

2. What is my main machining material?

3. Do I focus more on heavy roughing or precision finishing?

4. Will my production scale expand in the future?

5. Correct answers to these questions will help you avoid:

6. Over-investment

7. Underperformance

8. Repeated equipment upgrades

Conclusion

If your production involves large, heavy, or high-precision workpieces, a Double Column Machining Center is not an option—it is a necessity.

By clearly understanding:

1. When you truly need one

2. Which technical factors matter most

3. How to match machine capability to real production needs

4. You can build a stable, efficient, and scalable large-part machining production line.

ZOPO CNC is ready to support your large-part machining challenges with professional double column machining solutions.