What Are The Shapes Of Chips By Drill Processing?

- Share

- publisher

- Stitch

- Issue Time

- Oct 8,2025

Summary

This article explains the six common chip shapes formed during drilling iron—conical spiral, long-toothed, fan-shaped, transitional broken, Z-shaped, and needle-shaped. Each chip type reflects the cutting conditions such as feed rate, tool wear, material brittleness, and drilling speed. Understanding these chip formations helps optimize cutting parameters, improve chip removal, and enhance overall drilling efficiency and hole quality.

Title

When a drill cuts iron, it produces chips of various shapes. These shapes depend on a variety of factors, including the drill material, rotational speed, feed rate, and the material being cut. Understanding the shape characteristics of chip production is crucial for optimizing the drill process and improving production efficiency.

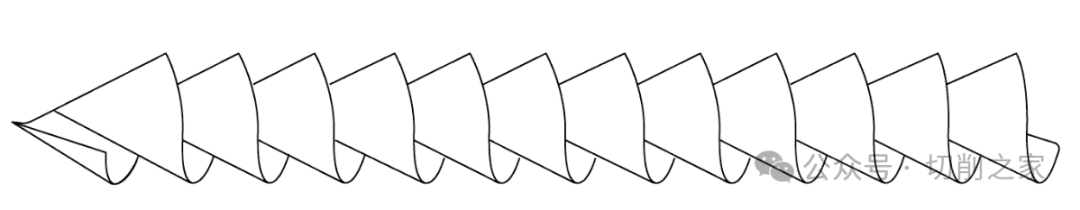

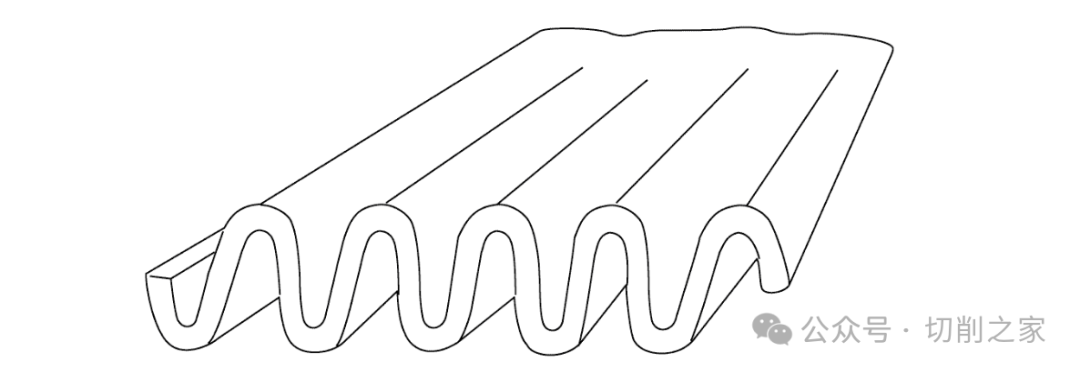

Conical spiral iron chips

Conical spiral chips are the basic shape used in drill processing. They are commonly found in drilling relatively low-hardness materials. They are easily dislodged when several coils are broken off. Initially, long chips are generated from the chisel edge to the cutting edge, but this is not a problem. If the feed rate is high, it is easy to break.

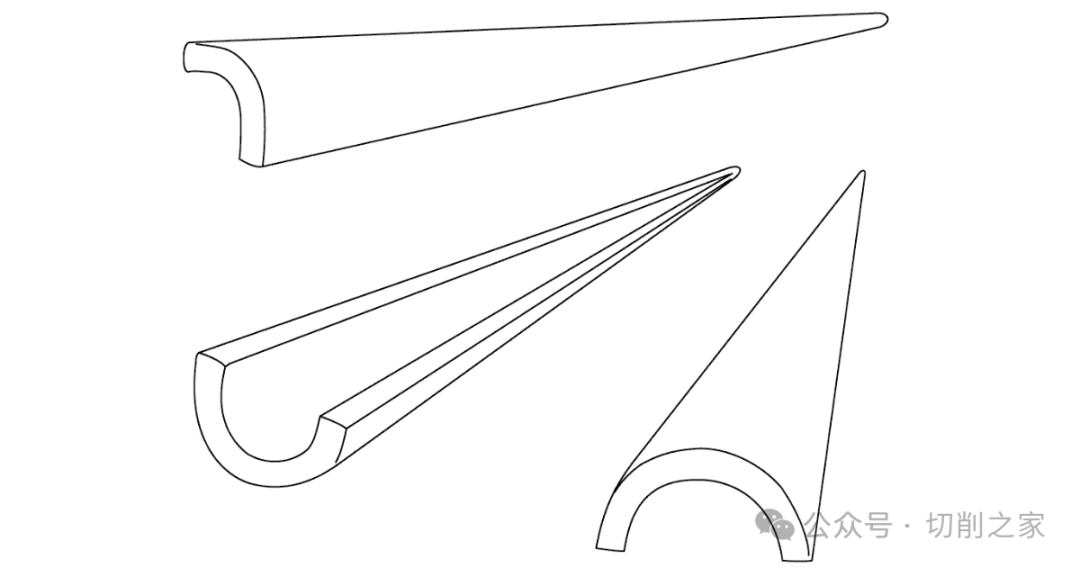

Long toothed iron chips

Chips with long teeth are discharged straight without curling, so they may cling to the drill flutes, blocking subsequent chips. Even if discharged, they may become entangled in the drill bit or chuck, resulting in poor hole accuracy or drill breakage. As the drill wears, the conical spiral shape may change to a long tooth shape.

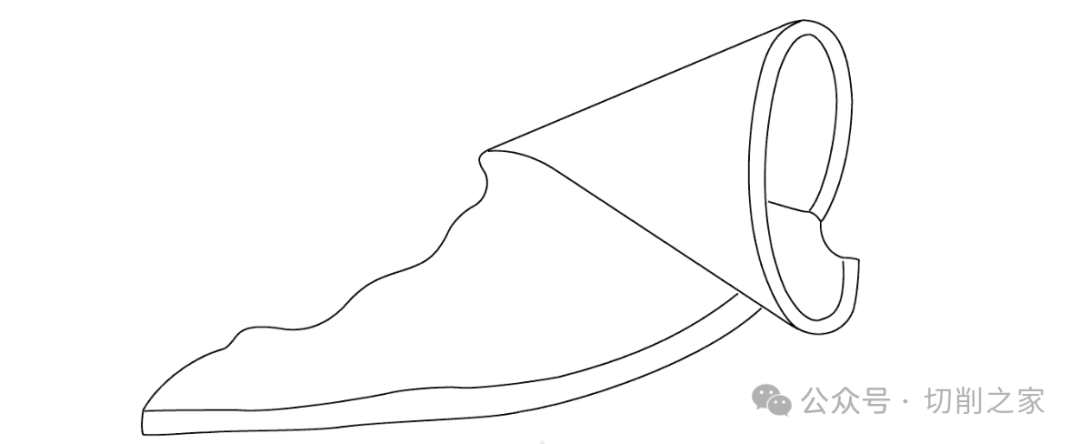

Fan-shaped iron chips

Fan-shaped chips are produced when feeding large amounts of steel or machining high-speed steel, and are a shape with good discharge properties.。

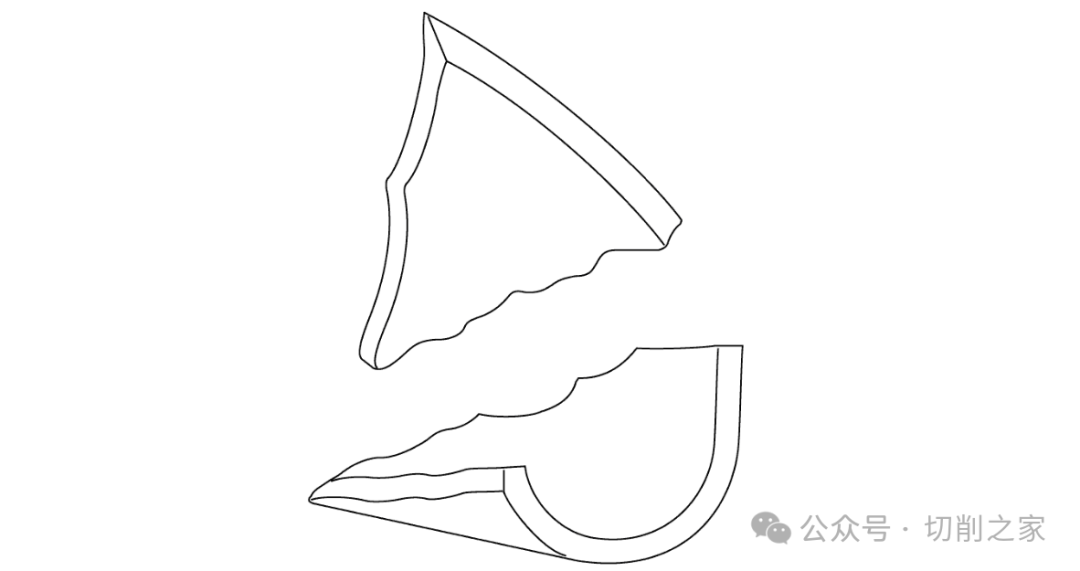

Transitional broken iron chips

Transitional fractured chips are initially curled into a conical spiral, but then break off at the base due to insufficient ductility in the workpiece when constrained by the inside of the machined hole. These chips are typically formed when the feed rate is slightly too high. The fluctuation in resistance during fracture causes vibration, which generally results in an undesirable chip shape.

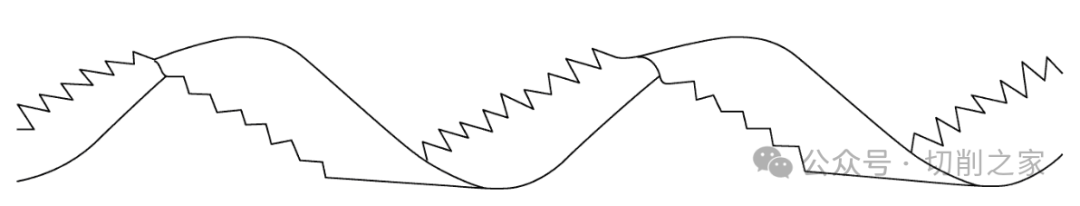

Z-shaped iron chips

Z-shaped iron chips are easily generated when the feed is small. The generated iron chips are folded and are prone to cause blockage.

Needle-shaped iron chips

Needle-shaped iron chips are easily generated when machining brittle workpieces and have good discharge properties. However, when performing downward machining, iron chips are prone to clogging, so care must be taken.