What is CNC Vertical Machining Center? A Comprehensive Guide

- Share

- publisher

- Stitch

- Issue Time

- Aug 25,2025

Summary

Meta Description: Discover ZOPO CNC's advanced CNC Vertical Machining Centers designed for precision, efficiency, and flexibility. Explore SE, VMC, and SV series for industries like aerospace, automotive, molds, and electronics.

Introduction

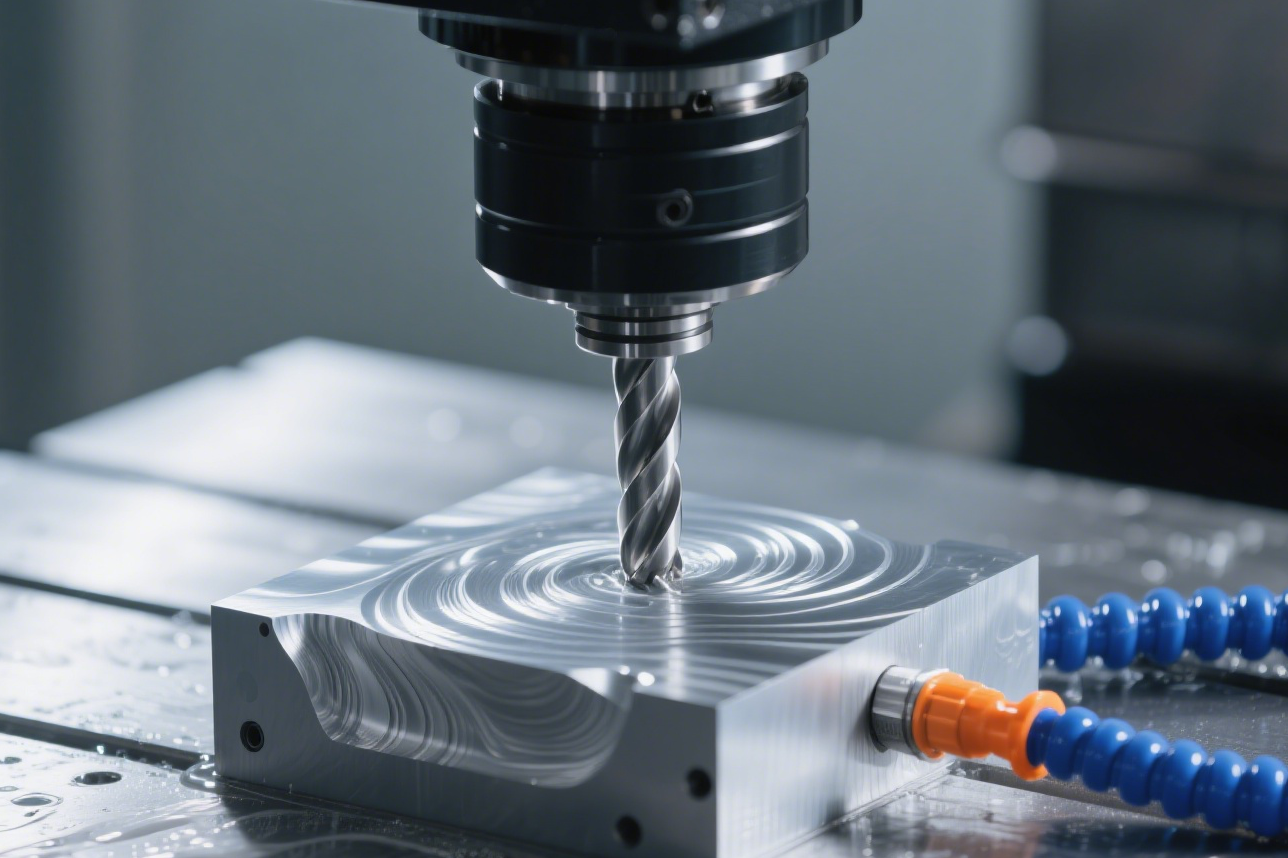

In today's competitive manufacturing environment, achieving both precision and efficiency is essential. A high-precision CNC vertical machining center provides manufacturers with the tools to produce complex parts, reduce cycle times, and increase profitability.

At ZOPO CNC, we design and manufacture cutting-edge CNC vertical machine centers that combine stability, innovation, and cost-effectiveness. Our machines are trusted by customers across the globe in industries ranging from aerospace to automotive and beyond.

What is a Vertical Machining Center ?

A vertical machining center is a type of CNC milling machine where the spindle is oriented vertically. This configuration makes it ideal for precision milling, drilling, tapping, and boring operations.

Compared to horizontal machining centers, VMCs offer:

Greater operator accessibility

More cost-effective investment

Excellent flexibility for multi-industry use

Advantages of CNC Vertical Machining Centers

1.High Precision: Stable spindle design and rigid structure ensure consistent accuracy.

2.Versatility: Compatible with metals, plastics, and composites.

3.Productivity Boost: Automatic tool changers and advanced CNC control reduce downtime.

4.User-Friendly Operation: Simplified programming and monitoring.

5.Cost-Performance Value: Balances affordability with high-end results.

Industry Benchmarks: Haas & DMG MORI

Global leaders such as Haas Automation and DMG MORI showcase the importance of VMC technology:

1.Haas Automation: VF Series and Mini Mills deliver affordable, reliable vertical milling solutions for small shops and large-scale manufacturers.

2.DMG MORI: NVX and DMP series highlight advanced automation, thermal stability, and ultra-high precision.

ZOPO CNC: High-Precision Vertical Machining Centers

At ZOPO CNC, we combine proven engineering with innovative solutions to create VMCs that meet diverse manufacturing needs.

Our Product Lines

SE Series: Entry-level efficient models for cost-sensitive operations.

VMC Series: Classic and versatile for general-purpose precision machining.

SV Series: High-performance machines engineered for complex and demanding applications.

Why ZOPO CNC?

Expertise: Years of experience in CNC R&D and intelligent manufacturing.

Trust: Machines trusted worldwide by industries from aerospace to electronics.

Customization: Tailored solutions for unique production needs.

Support: Global after-sales service ensures reliability and peace of mind.

Applications of ZOPO CNC Vertical Machining Centers

Automotive: High-volume precision component machining.

Aerospace: Lightweight, complex part production with tight tolerances.

Electronics: Delicate and accurate small parts manufacturing.

Mold & Die: Superior surface finishes and high-durability molds.

Customer Success Stories

Automotive Client: Boosted productivity by 30% after adopting ZOPO VMC solutions.

Aerospace Manufacturer: Reduced machining cycle times by 50% with ZOPO's SV Series.

Conclusion & Call to Action

A high-precision CNC vertical machining center is the backbone of modern manufacturing. With ZOPO CNC, you gain access to innovative solutions that combine performance, affordability, and long-term reliability.