CIMT 2025 Brings Together The Latest CNC And Five-Axis Machining Technologies, Driving Manufacturing Upgrades.

- Share

- publisher

- Stitch

- Issue Time

- Apr 30,2025

Summary

ZOPO Intelligent showcased five advanced machining centers at CIMT 2025, highlighting AI diagnostics, precision enhancement, multi-axis machining, and innovative designs for smarter, more efficient manufacturing.

Introduction

On April 15, 2025, the 18th China International Machine Tool Exhibition (CIMT 2025) opened grandly at the China International Exhibition Center in Beijing. With the theme of "Intelligent Manufacturing·Driving the Future", this exhibition brings together more than 1,500 companies from more than 30 countries and regions around the world, comprehensively displaying the latest CNC machine tools, industrial robots and intelligent manufacturing solutions.

Exhibition Highlights

The exhibition has a total area of 140,000 square meters and has 8 theme exhibition areas, covering high-precision CNC lathes, five-axis machining centers, additive manufacturing, industrial Internet of Things and other fields.

Highlights of corporate exhibitions

SVD650 Smart Vertical Machining Center

The SVD650 is equipped with the AI-powered DeepSeek Voice Assistant for rapid fault diagnosis through intuitive human-machine interaction. It features remote monitoring and predictive maintenance, integrated contour error compensation for precision enhancement, AI-driven smart programming, and comprehensive process optimization for higher efficiency and ease of operation.

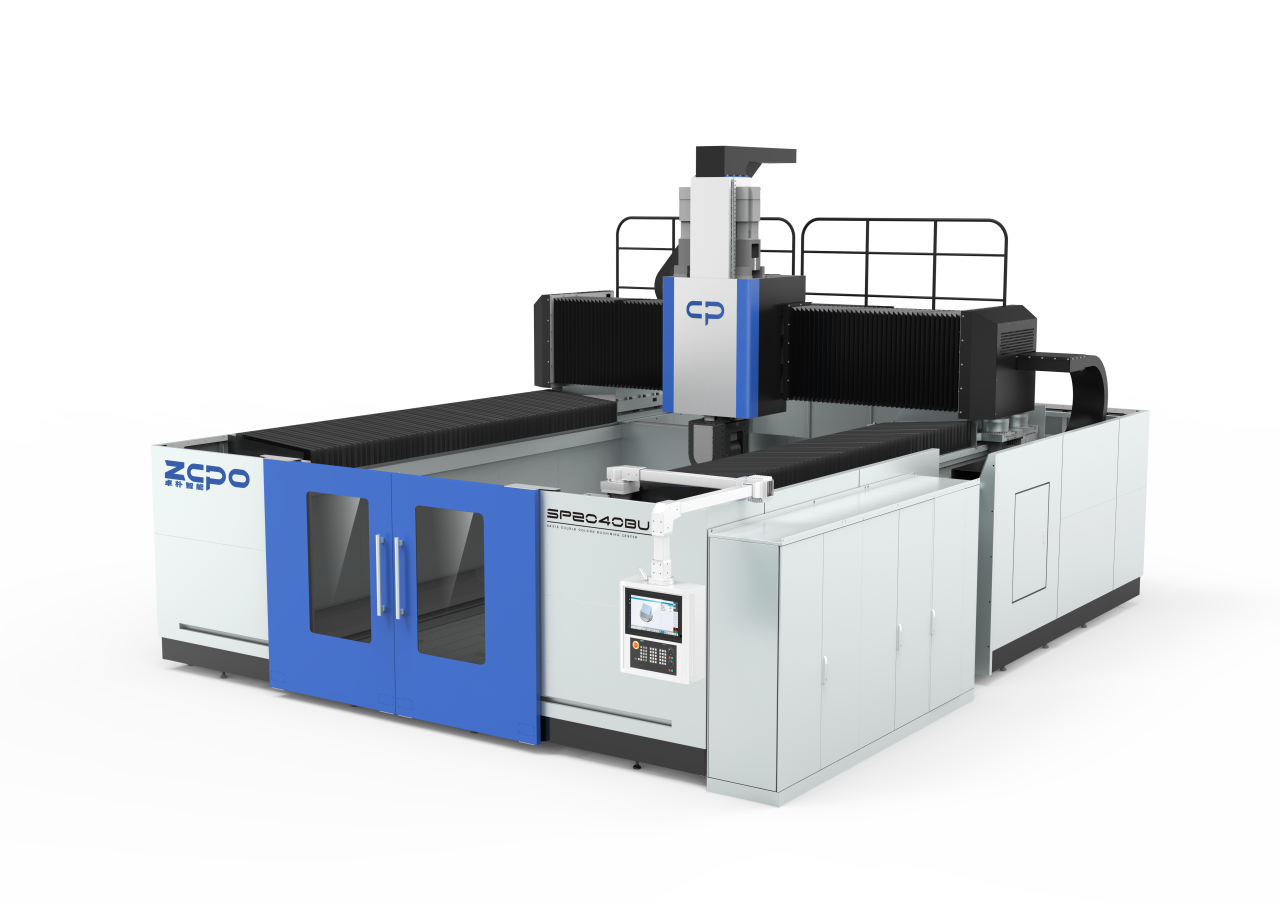

SP2040BU Bridge-type 5-axis Machining Center

The SP2040BU features 5-axis double screws synchronous driving and Y-axis double screws synchronous driving with a linear encoder in the center position for enhanced accuracy. It includes self-developed adaptive damping feet, adjustable hydraulic buffers for controlled stops, a fully cooled feed drive system for stability, and advanced vibration monitoring with fault diagnosis capabilities.

HMC63 Horizontal Machining Center

The HMC63 adopts an optimized one-piece T-shaped frame with a gantry-column design and front-mounted spindle case for higher rigidity. The high-low stepped structure enhances support for large-diameter drilling and boring, while its lightweight, efficient moving components enable both small-diameter drilling/tapping and large-hole precision boring.

VTM500 Vertical Turn & Mill

The VTM500 integrates turning and milling with multi-axis simultaneous machining. Its large-scale, wide-span structure is built with high-rigidity roller linear guideways. A large diameter hirth coupling, hydraulic lock turret, and hydraulic tool change system ensure stability and versatility. The VTM500 is ideal for high-complexity, low-volume, high-value-added part processing.

SHL5OH Hydrostatic spindle slant-bed CNC lathe

1.SHL50H CNC lathe adopts hydrostatic spindle technology, utilizingoil film support to achieve um level machining accuracy. lt enablessingle-pass of high-hardness materials through turning instead ofgrinding, with surface roughness Ra s 0.1um.

2.The hydrostatic spindle features zero-wear characteristics, with axial/radial stiffness reaching 200N/um. lt supports high-speed heavycutting operations, eliminates ripple, making it particularly suitable forultra-precision machining applications such as optical componentsand hydraulic valve cores.

Driving Industry Transformation

CIMT 2025 provided ZOPO Intelligent with a global stage to showcase its latest innovations, reflecting key industry trends such as smart manufacturing, precision enhancement, and integrated process solutions. By combining AI, advanced mechanics, and intelligent control, ZOPO continues to deliver high-value solutions that empower manufacturers worldwide to achieve greater productivity and quality.