Vertical Machining Center|V8P Direct spindle|Versatile Applications for Metal Processing

- Model

- V8P

Item specifics

- BRAND

- ZOPOCNC

- CNC

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- DIRECT SPINDLE

- CONTROL

- SEMI-CLOSED LOOP CONTROL

Review

Description

Vertical Machining Center

V8P

High rigidity for heavy cutting

Heavy stock removal, tough materials, highrigidity/torque, precision for mold/engineeringmachinery.

850/500/550mm

X/Y/Z axis travel

500×1000mm

Worktable size

12000rpm

Spindle speed

48/48/48m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Appearance

Charasteristics

High rigidity, high efficiency and high stability structural design

Hot sale 10000+ units

Excellent overall performance, high cost performance

- The unique arc-shaped base design after finite element analysis and the internal reinforcement rib layout provide better processing rigidity among machine tools of the same size.

- The base adopts a large-span structure with two 45mm roller linear guideways, which provides the machine with very strong load-bearing capacity while meeting the high rigidity requirements during heavy cutting.

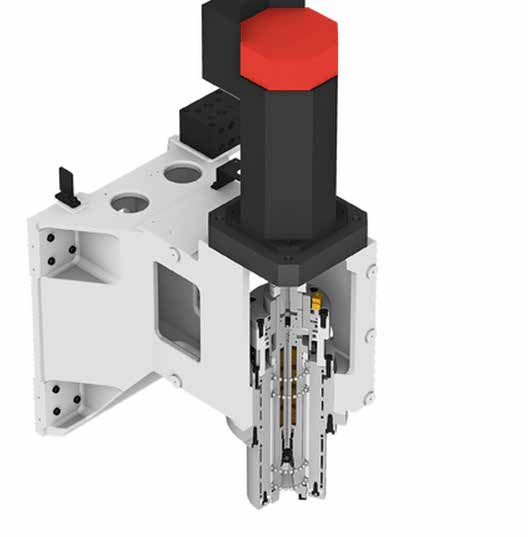

Direct spindle

- The integrated structure of the spindle box and motor seat reduces the cumulative error of the motor seat assembly

- Greatly improve processing efficiency and quality

- Extend tool life and reduce processing costs

Superior processing capabilities

The V series machine tools with stable cutting performance are suitable for automotive parts, 3C industry, military industry, molds, sewing equipment and diversified product processing applications in the ever-changing market.

Parameters

Working range

Unit

- X/Y/Z axis travel

- 850/500/550mm

- Distance from column to spindle center

- 582mm

- Distance from table surface to spindle nose

- 120-670mm

Worktable

Unit

- Worktable size

- 500x1000mm

- T-slot size

- 5-18*100mm

- Max. load bearing of worktable

- 500kg

Spindle

Unit

- Spindle hole taper

- BT40

- Main motor power

- 7.5/11KW

- Spindle speed

- 12000(direct)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 48/48/48m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 2.5S

Machine

Unit

- Machine dimension

- 2978*2490*2885mm

- Machine weight

- 5500kg