SVD1270 Direct Spindle

- Model

- SVD1270

Item specifics

- BRAND

- ZOPO INTELLIGENT

- CNC system

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- DIRECT SPINDLE

- CONTROL

- Semi-closed loop control

Review

Description

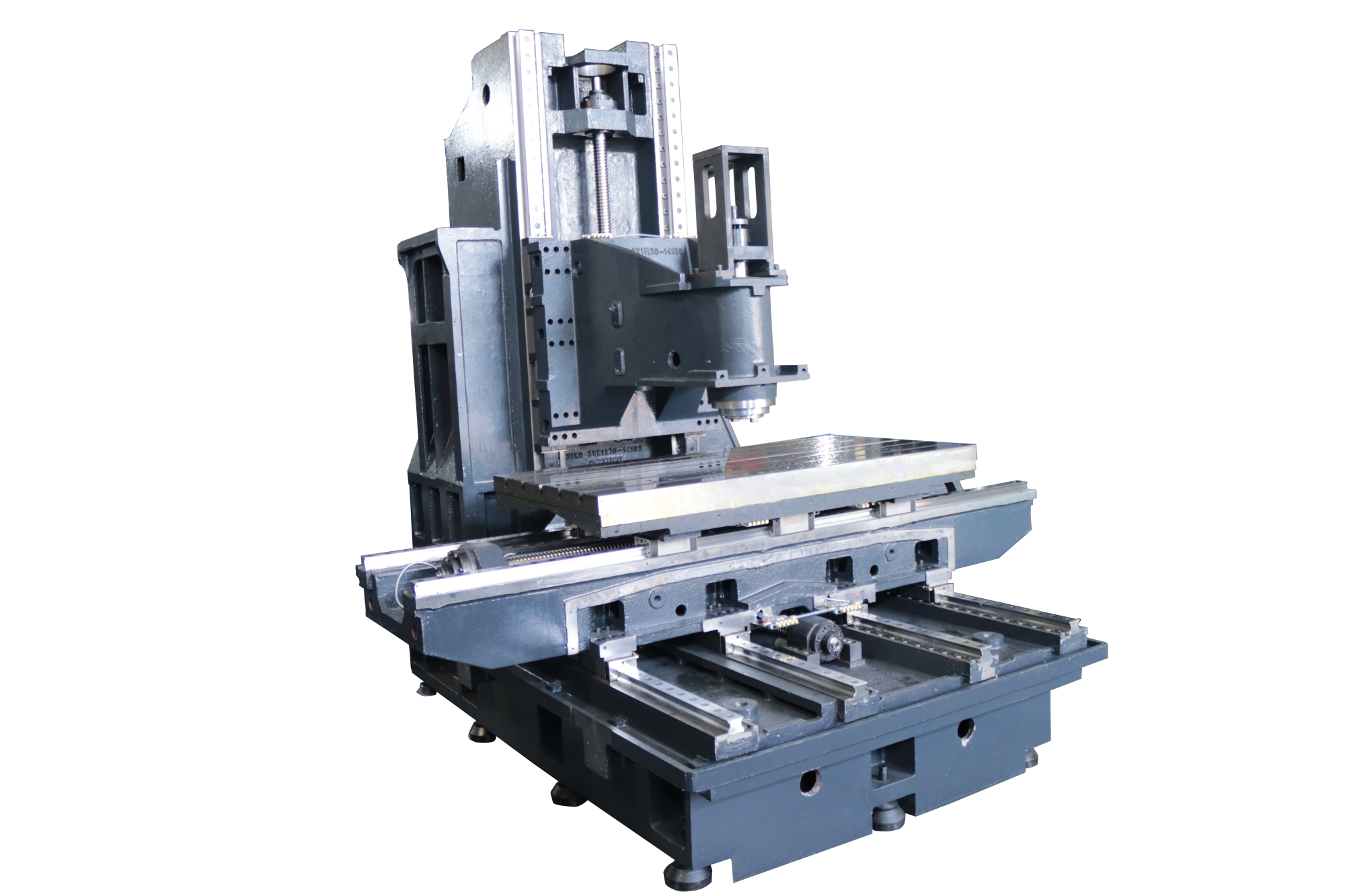

SVD1270

High speed and high efficiency model

The best choice for processing performance and processing range in the same level

1200/700/700mm

X/Y/Z axis travel

700×1400mm

Worktable size

10000rpm

Spindle speed

24/24/20m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Appearance

Charasteristics

Stable and reliable structure

- The solid dense-baked casting and integral box-type bed and arched column structure improve the basic rigidity of the machine.

- The unique cross-section design of the base component after finite element analysis and the reasonable distribution of internal reinforcement ribs give it higher load-bearing rigidity among products of the same specifications.

- The three-axis transmission seat and tail end bracket adopt an integrated casting design, eliminating the traditional split and shim adjustment mechanism, greatly improving the accuracy and stability of the machine's three-axis transmission.

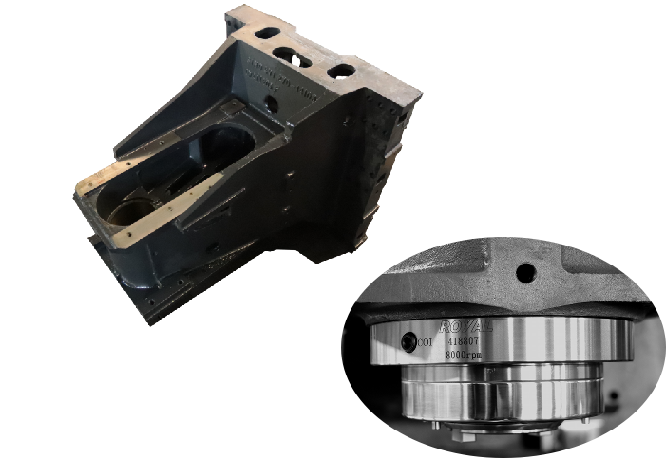

Closed spindle box

The spindle box adopts a closed box structure, the contact size with the column guide rail is enlarged, and the overall lightweight design. The short nose spindle is standard, which improves the Z-axis positioning accuracy and spindle processing stability during the machine processing.

Direct spindle

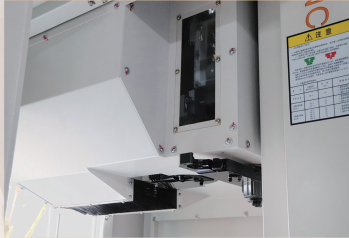

Stable and reliable tool changing device

Parameters

Working range

Unit

- X/Y/Z axis travel

- 1200/700/700mm

- Distance from column to spindle center

- 766mm

- Distance from table surface to spindle nose

- 150-850mm

Worktable

Unit

- Worktable size

- 700x1400mm

- T-slot size

- 5-18*125mm

- Max. load bearing of worktable

- 1000kg

Spindle

Unit

- Spindle hole taper

- BT50

- Main motor power

- 11/15KW

- Spindle speed

- 10000(Direct)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 24/24/24m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 3.5S

Machine

Unit

- Machine dimension

- 4

- 4350*2955*3320mm

- Machine weight

- 9700kg