SVB850 Belt spindle

- Model

- SVB850

Item specifics

- BRAND

- ZOPOCNC

- CNC

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- BELT SPINDLE

- CONTROL

- SEMI-CLOSED LOOP CONTROL

Review

Description

SVB850

High rigidity and high precision model

The best choice for processing performance and processing range in the same level

850/520/560mm

X/Y/Z axis travel

500×1000mm

Worktable size

8000rpm

Spindle speed

48/48/32m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Appearance

Charasteristics

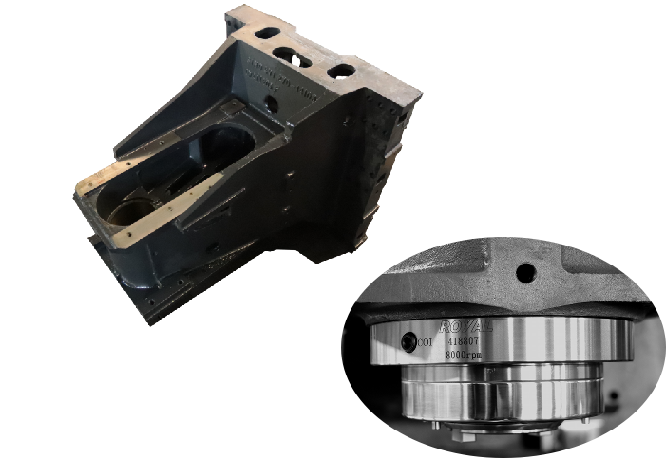

Stable and reliable structure

- The solid dense-baked casting and integral box-type bed and arched column structure improve the basic rigidity of the machine tool.

- The unique cross-section design of the base component after finite element analysis and the reasonable distribution of internal reinforcement ribs give it higher load-bearing rigidity among products of the same specifications.

- The three-axis transmission seat and tail end bracket adopt an integrated casting design, eliminating the traditional split and shim adjustment mechanism, greatly improving the accuracy and stability of the machine tools three-axis transmission.

Closed spindle box

The spindle box adopts a closed box structure, which increases the contact size with the column guideway and adopts a lightweight design as a whole. In addition, the short nose spindle is standard, which improves the Z-axis positioning accuracy and spindle processing stability during the machine tool processing.

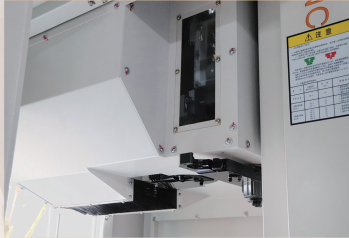

Stable and reliable tool changing system

Parameters

Working range

Unit

- X/Y/Z axis travel

- 850/520/560mm

- Distance from column to spindle center

- 592mm

- Distance from table surface to spindle nose

- 120-680mm

Worktable

Unit

- Worktable size

- 500x1000mm

- T-slot size

- 5-18*100mm

- Max. load bearing of worktable

- 600kg

Spindle

Unit

- Spindle hole taper

- BT40

- Main motor power

- 7.5/11KW

- Spindle speed

- 8000(belt)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 48/48/32m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 2.5S

Machine

Unit

- Machine dimension

- 2250*2700*2850mm

- Machine weight

- 6800kg