Double Column Machining Center|SP1830II Gearhead T type Ram

- Model

- SP1830II

Item specifics

- BRAND

- ZOPO INTELLIGENT

- SYSTEM

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- GEARHEAD

- CONTROL WAY

- Semi-closed loop control

Review

Description

SP1830II

II Upgraded T-type ram series

The first choice for large workpiece processing in industries such as large molds, mechanical parts, petroleum, aviation, rail transportation, etc.

3200/2400/1000mm

X/Y/Z axis travel

1800x3000mm

Worktable size

6000rpm

Spindle speed

15/15/10m/min

Rapid feed speed

- Model

- Appearance

- Characteristics

- Parameters

- Contact Us

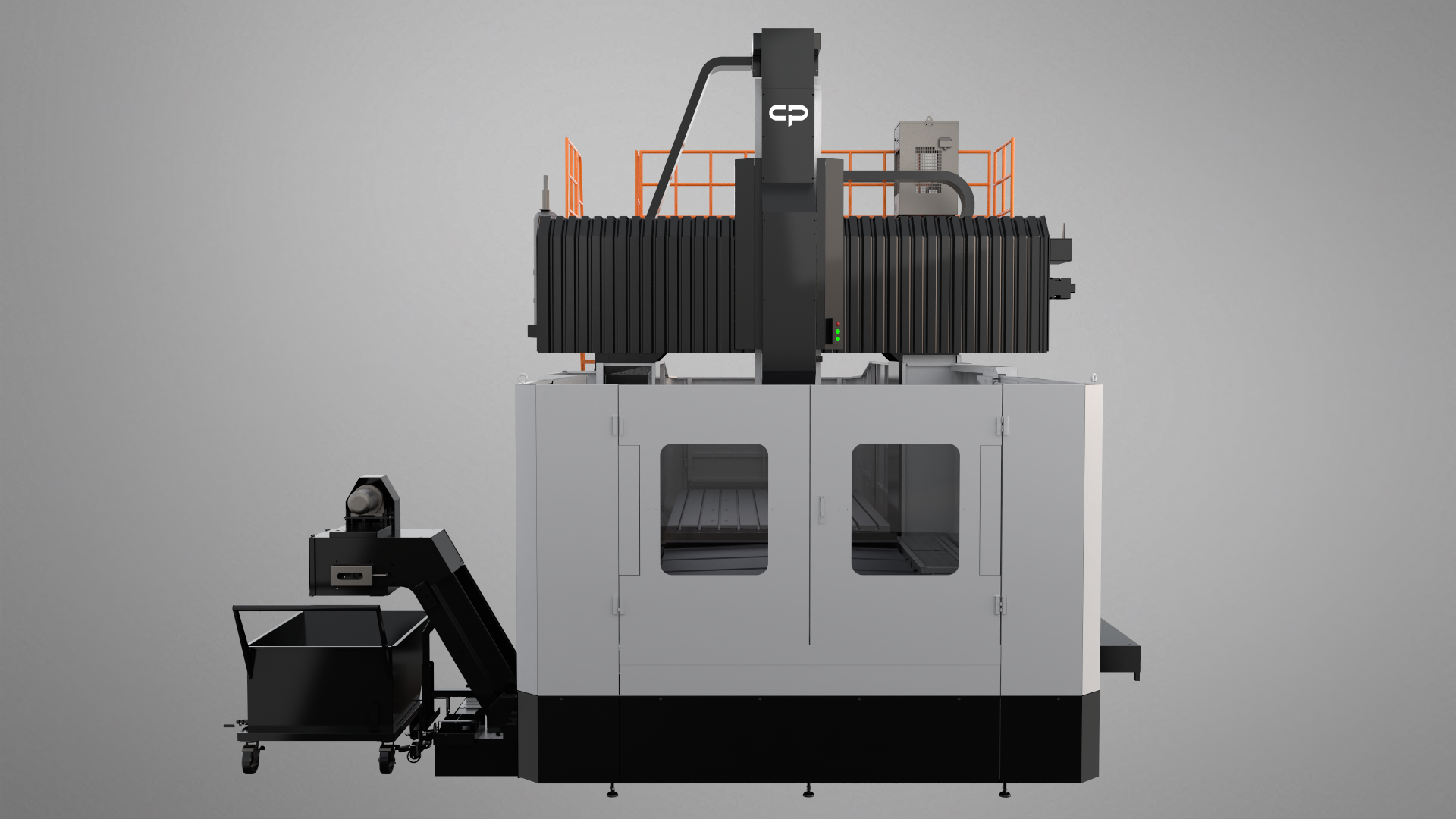

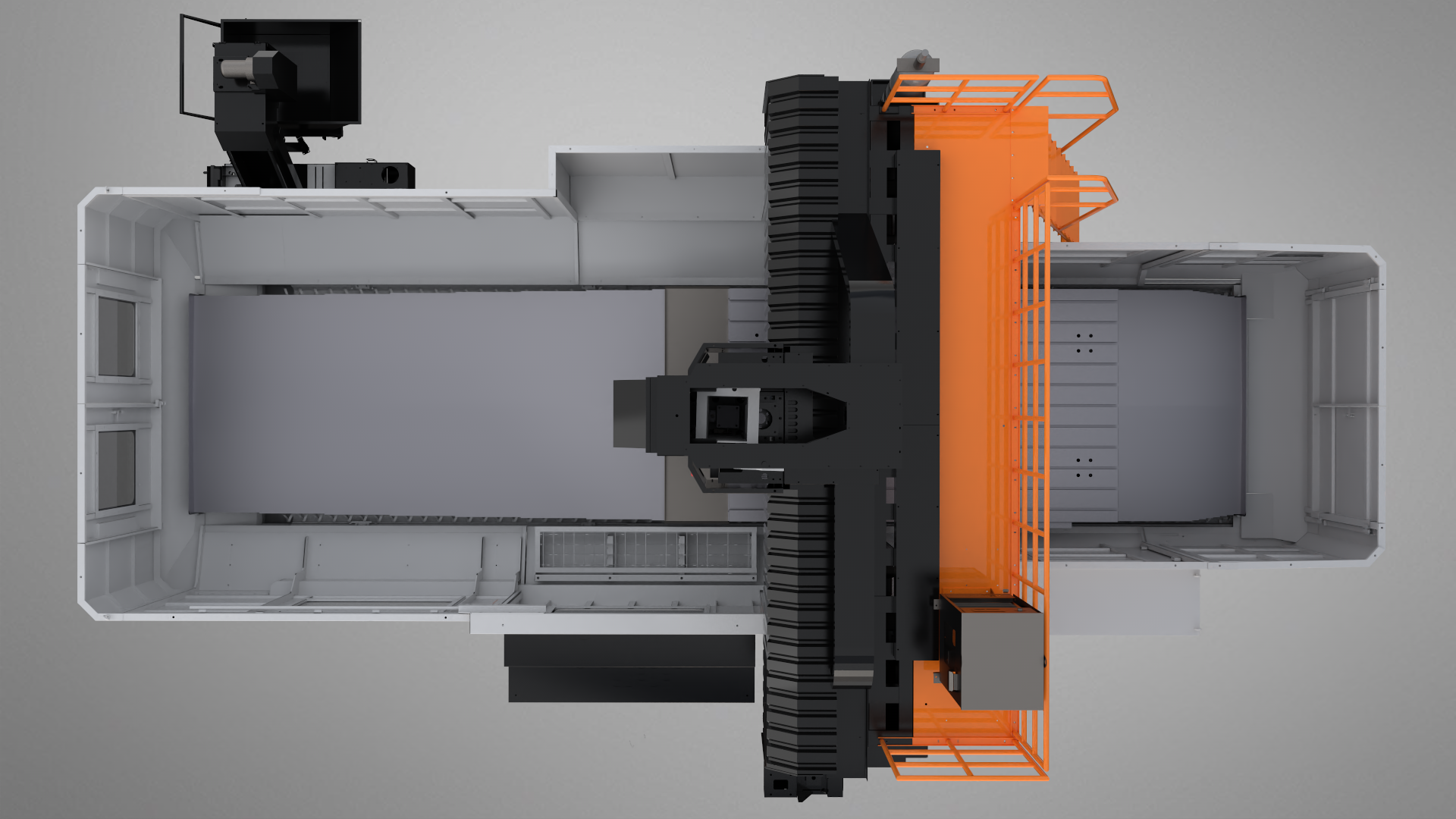

Appearance

Characteristics

Serialized and modular design

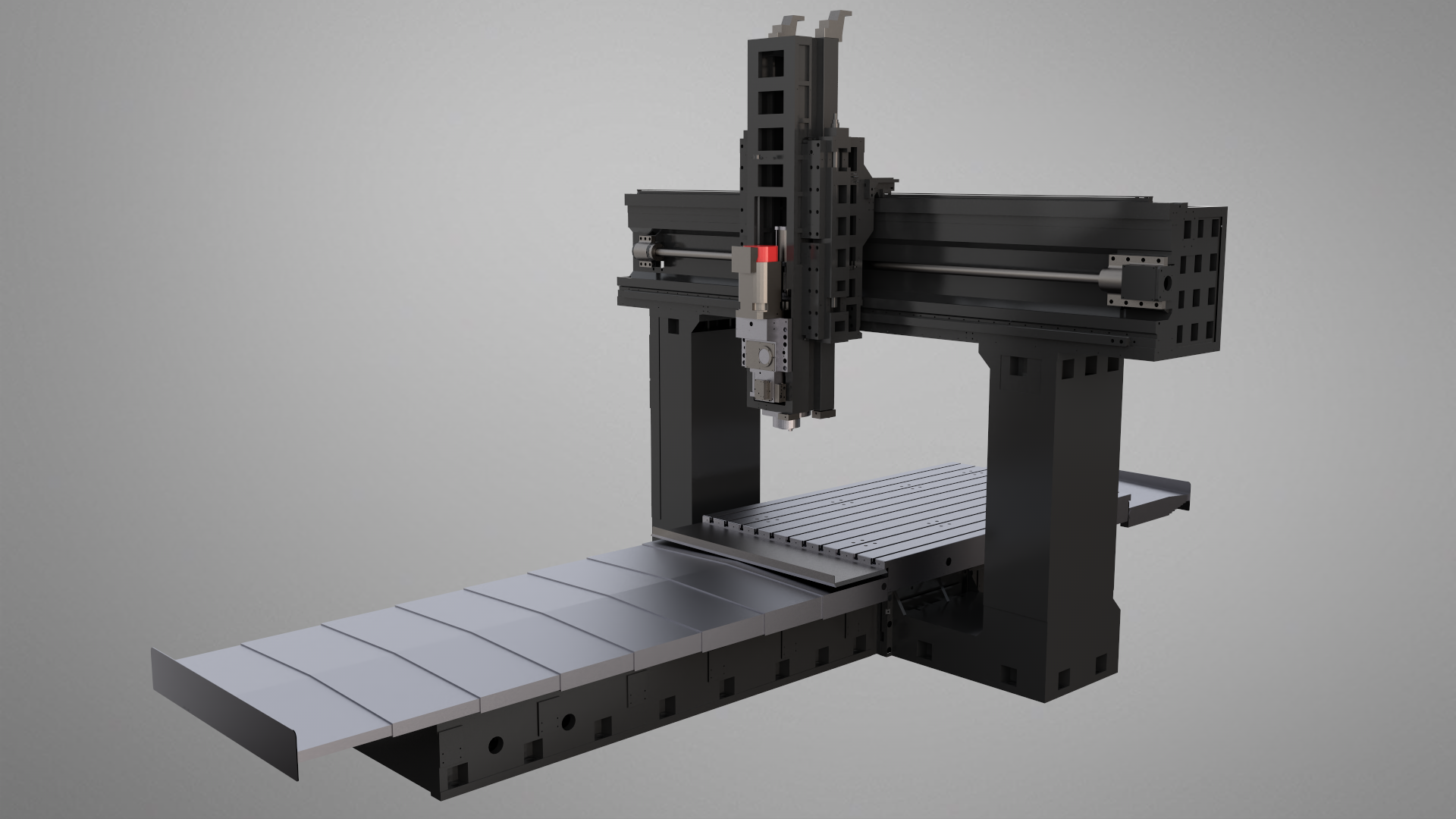

Large span, long travel, high stability structural design

All castings are made of high-strength gray cast iron with vibration absorption ability, and are aged to ensure stability. The reinforcing ribs are well designed to have excellent bending resistance to ensure the stability of the machine.

- Ram:The double balance bars are symmetrically distributed on both sides to improve the precision of the moving parts of the ram.

- Worktable:The worktable is hollowed out, the T-slot spacing on the table is 200mm, and the moving parts are lightweight, which improves the responsiveness of the machine during dynamic processes.

- Machine body:The one-piece casting body and the larger span of the body rails effectively enhance the load-bearing capacity of the worktable.

- Beam:The guideways on the crossbeam and saddle joint surfaces are distributed vertically and orthogonally to improve the overall rigidity and precision stability of the machine.

- Two column distance:The full range of two column distance and Y travel are designed to maximize the range of machine, and can be freely equipped with a variety of accessory milling heads; effectively improving the processing capacity of the machine.

Easier to use and more powerful control system

Relying on the in-depth collaboration between ZOPO software development engineers and CNC system companies, we continuously carry out secondary development based on standard CNC systems to create multi-functional and intelligent human-machine interfaces, creating a more efficient and convenient user experience for customers.

- Energy-efficient processing mode selection

- Tool management function

- Broken blade detection function

- Troubleshooting guide function

- Super strong human-computer interaction interface

Parameters

Working range

Unit

- X/Y/Z axis travel

- 3200/2400/1000mm

- Distance between two columns

- 2400mm

- Distance from table surface to spindle nose

- 220-1220mm

Worktable

Unit

- Worktable size

- 1800x3000mm

- T-slot size

- 9-22*200mm

- Max. load bearing of worktable

- 12000kg

Spindle

Unit

- Spindle hole taper

- BT50

- Main motor power

- 15/18.5(wide area)

- Spindle speed

- 6000(Gearhead)rpm

Feed

Unit

- Max. feed speed

- 8000mm/min

- Rapid feed rate

- 15/15/10m/min

Machine

Unit

- Machine dimension

- 8800*6200*5500mm

- Machine weight

- 34000kg