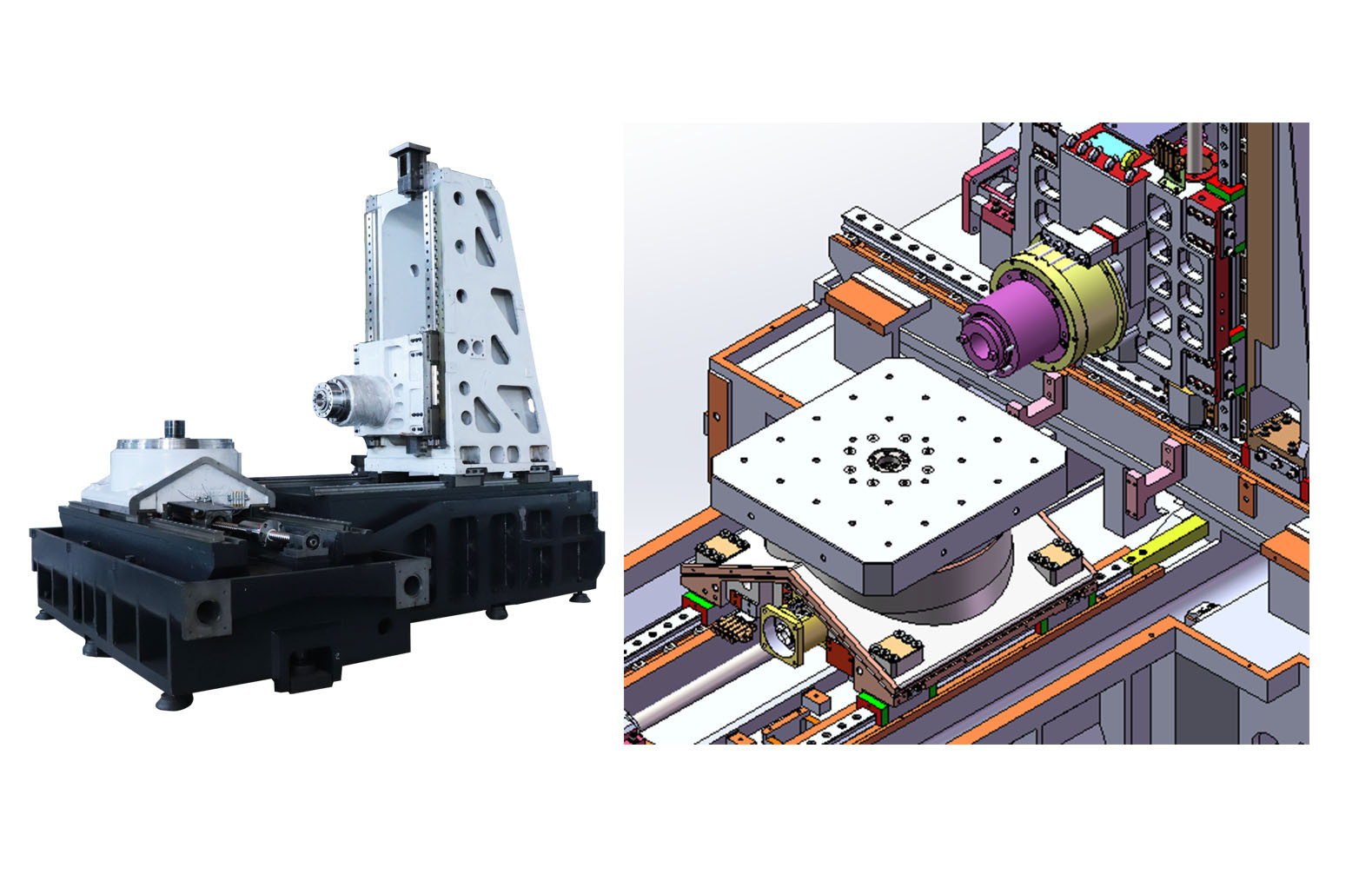

HMC1250A Inverted T type Single worktable

- Model

- HMC1250A

Item specifics

- BRAND

- ZOPO CNC

- CNC

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- BELT SPINDLE

- CONTROL

- SEMI-CLOSED LOOP CONTROL

Review

Description

HMC1250A

INVERTED T TYPE SINGLE WORKTABLE

Ideal choice for big batch automation processing lines

2400/1300/1300mm

X/Y/Z axis travel

1250x1250mm

Worktable size

5300rpm

Spindle speed

20/20/20m/min

Rapid feed speed

- Model

- Appearance

- Characteristics

- Parameters

- Contact Us

Appearance

Characteristics

Machine structure

“┻” shape and column moving structure to afford high rigidity and travel speed;

All the machine parts adopted finite element analysis.

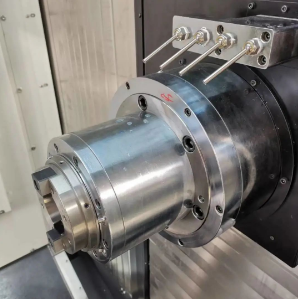

Spindle

BT50 high tension spindle.

Broaching force 1800kgf (17640N).

Less prone to vibration during processing.

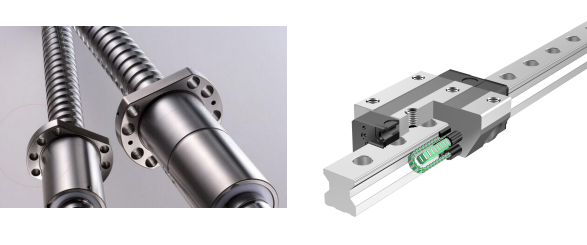

High precision double nut ball screw

Guaranteed heavy cutting

Ensure machining accuracy

Extend the service life of the lead screw

3 axes rapid feed speed: 20/20/20m/min

High rigidity, high precision

Low noise roller type linear guideway

Ensure high stability

Man-machine interaction

Vertical stainless steel armor protection design, Better chip removal.

Combined with steeply sloped chip flutes, reduce manual cleanup time.

Parameters

Working range

Unit

- X/Y/Z axis travel

- 2400/1300/1300mm

- Distance from spindle center to table surface

- 140-1440mm

- Distance from spinlde nose to table surface

- 450-1750mm

Worktable

Unit

- Worktable size

- 1250x1250mm

- Workpiece clamping type

- 7-22x125

- Rotary diameter of workpiece

- Φ3200

- Max. load bearing of worktable

- 3000kg

Spindle

Unit

- Spindle hole taper

- BT50

- Spindle power

- 15/18.5KW

- Max. spindle speed

- 5300rpm

Feed

Unit

- Max. feed speed

- 5300mm/min

- Rapid feed speed

- 20/20/20m/min

Tool magzine

Unit

- Tool magzine capacity

- 24T

- Tool changing time

- 5.5S

Machine

Unit

- Machine dimension

- 7000*5800*4000mm

- Machine weight

- 22000kg