Vertical Machining Center |VMC1000P Belt spindle|High Precision Metal Cutting Solutions

- Model

- VMC1000P

Item specifics

- BRAND

- ZOPOCNC

- CNC

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- BELT SPINDLE

- CONTROL

- SEMI-CLOSED LOOP CONTROL

Review

Description

Vertical Machining Center

VMC1000P

High rigidity for heavy cutting

Heavy stock removal, tough materials, highrigidity/torque, precision for mold/engineeringmachinery.

1000/520/535mm

X/Y/Z axis travel

520×1200mm

Worktable size

8000rpm

Spindle speed

48/48/32m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Appearance

Charasteristics

High rigidity, high efficiency and high stability structural design

Hot sale 10000+ units

Excellent overall performance, high cost performance

- The unique arc-shaped base design after finite element analysis and the internal reinforcement rib layout provide better processing rigidity among machine tools of the same size.

- The base adopts a large-span structure with two 45mm roller linear guideways, which provides the machine with very strong load-bearing capacity while meeting the high rigidity requirements during heavy cutting.

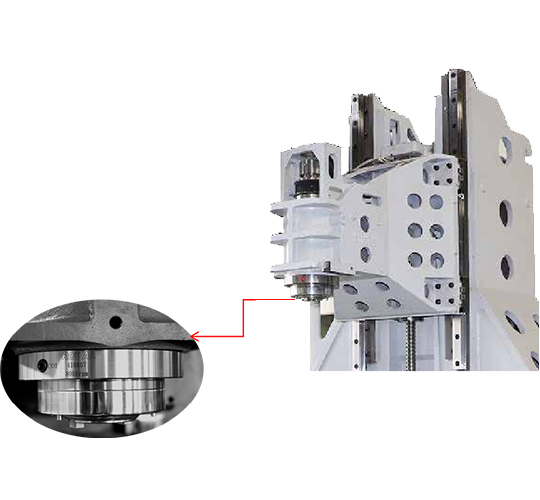

High performance spindle

- The spindle box guideway is designed with a large cross-section and the structure is optimized to be the best among similar models. It is equipped with a Z-axis weightless structure to ensure the stability and accuracy of vertical high-speed positioning.

- The Z-axis guideway span is larger than that of traditional models, which greatly improves the contact ratio between the spindle box and the column, ensuring high torque of the spindle during processing.

- The short nose spindle ensures the cutting rigidity of the machine.

Superior processing capabilities

The VMC series machine tools with stable cutting performance are suitable for automotive parts, 3C industry, military industry, molds, sewing equipment and diversified product processing applications in the ever-changing market.

Parameters

Working range

Unit

- X/Y/Z axis travel

- 1000/520/535mm

- Distance from column to spindle center

- 582mm

- Distance from table surface to spindle nose

- 80-615mm

Worktable

Unit

- Worktable size

- 520x1200mm

- T-slot size

- 5-18*100mm

- Max. load bearing of worktable

- 500kg

Spindle

Unit

- Spindle hole taper

- BT40

- Main motor power

- 11/15KW

- Spindle speed

- 8000(belt)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 48/48/32m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 2.5S

Machine

Unit

- Machine dimension

- 2990*2490*2885mm

- Machine weight

- 6400kg