SVB1570 Belt spindle

- Model

- SVB1570

Item specifics

- BRAND

- ZOPO INTELLIGENT

- CNC system

- FANUC/SIEMENS/MITSUBISHI

- SPINDLE

- BELT SPINDLE

- CONTROL

- Semi-closed loop control

Review

Description

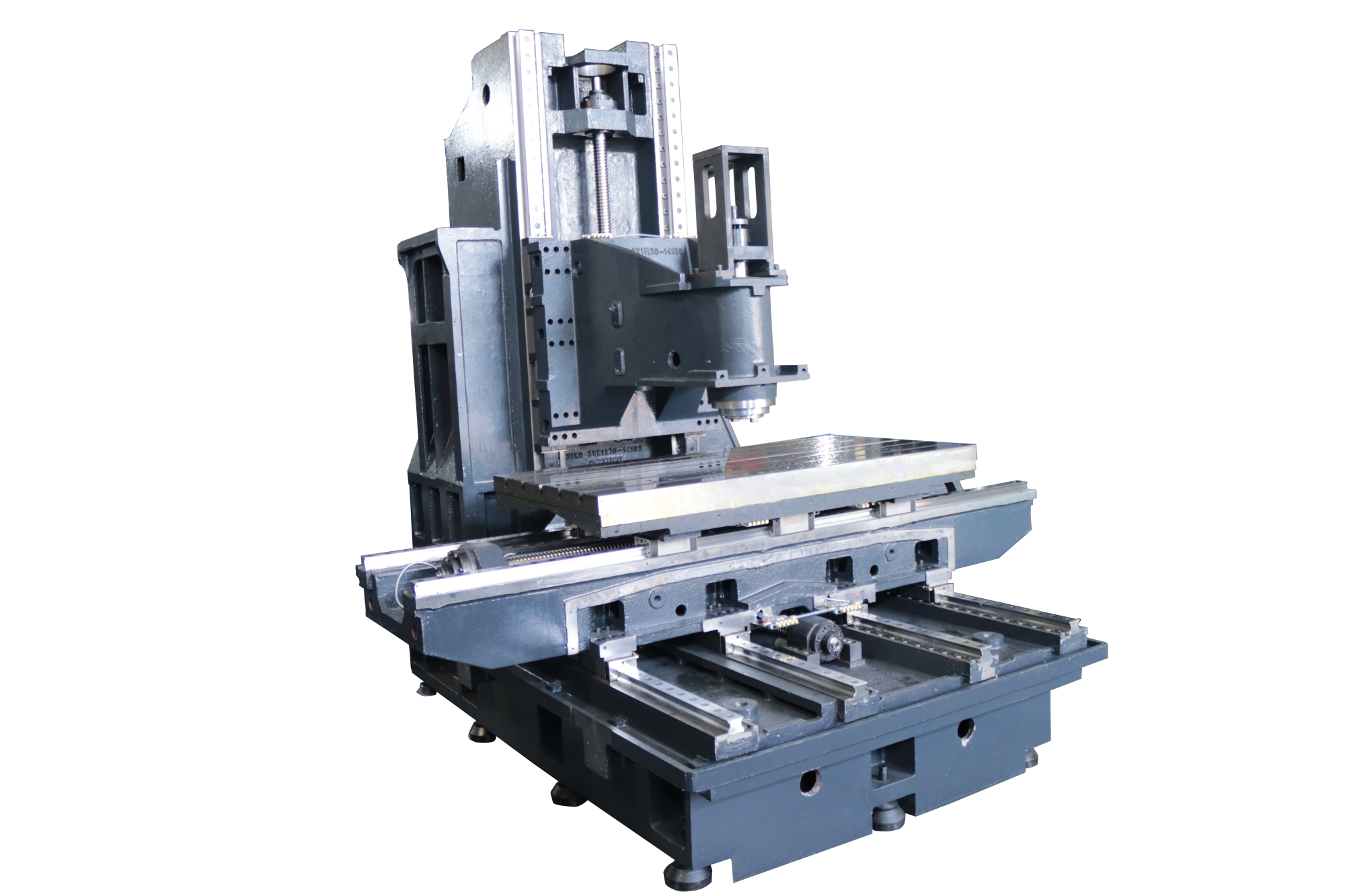

SVB1570

Pan-aluminum processing

Long travel, high speed, best choice for processing large-size aluminum products

1500/700/700mm

X/Y/Z axis travel

700×1600mm

Worktable size

10000rpm

Spindle speed

20/20/20m/min

Rapid feed speed

- Model

- Appearance

- Charasteristics

- Parameters

- Contact Us

Appearance

Charasteristics

Stable and reliable structure

- The Y-axis uses four 45mm high-rigidity and high-load roller linear guideways and heavy-duty 8-slide blocks to enhance rigidity and load-bearing capacity.

- Convenient and efficient chip handling: The machine is equipped with two screws as standard to effectively discharge the chips generated during processing, with high conveying efficiency.

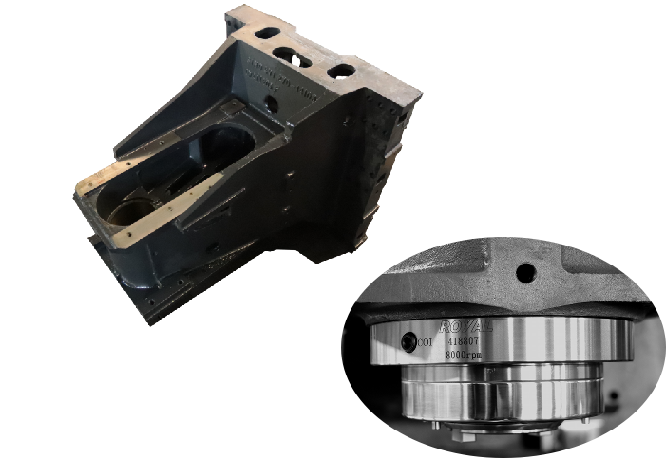

Closed spindle box

The spindle box adopts a closed box structure, the contact size with the column guide rail is enlarged, and the overall lightweight design. The short nose spindle is standard, which improves the Z-axis positioning accuracy and spindle processing stability during the machine tool processing.

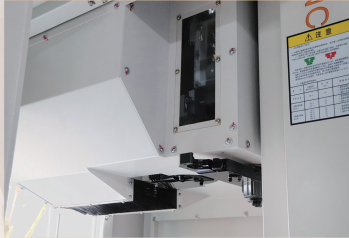

Stable and reliable tool changing device

Parameters

Working range

Unit

- X/Y/Z axis travel

- 1500/700/700mm

- Distance from column to spindle center

- 766mm

- Distance from table surface to spindle nose

- 140-840mm

Worktable

Unit

- Worktable size

- 700x1600mm

- T-slot size

- 5-18*125mm

- Max. load bearing of worktable

- 1000kg

Spindle

Unit

- Spindle hole taper

- BT40

- Main motor power

- 11/15KW

- Spindle speed

- 10000(Belt)rpm

Feed

Unit

- Max. feed speed

- 12000mm/min

- Rapid feed speed

- 20/20/20m/min

Tool magazine

Unit

- Tool magazine capacity

- 24T

- Tool change time

- 2.5S

Machine

Unit

- Machine dimension

- 3950*3300*3320mm

- Machine weight

- 9800kg