SHL40PC High-application Driven-Turret

- Model

- SHL40PC

Item specifics

- Brand

- ZOPO Intelligent

- CNC

- Fanuc/Siemens/Mitsubishi/GNC/KND

- Spindle Hole Taper

- A2-5

- Control Mode

- Semi-closed loop

Review

Description

SHL40PC

High Capability

High Efficiency, Compact Design, Low Cost

Φ400mm

Max.Swing Over Bed

300mm

Max.Turning Length

Φ320mm

Max.Turning Dia

A2-5

Spindle Hole Taper

- Model

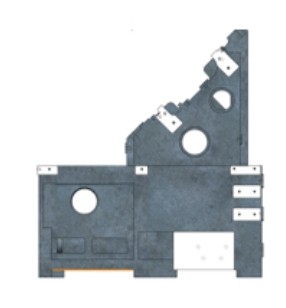

- Appearance

- Characteristic

- Parameters

- Contact Us

Appearance

Characteristic

Compact Design&High Efficenty

The compact design occupy smaller space, and easy to install and use.

The gang tool layout can quickly change tools, reduce tool changing time, and improve processing efficiency.

High Rigidity Structure

The design of the body and components has high rigidity, which can ensure stability during the machining process, reduce vibration and deformation, and improve the processing accuracy.

Flexible Processing

Suitable for processing various axis and disc parts, capable of completing various machining processes such as turning, drilling, boring, tapping, etc., and with high scalability, it can adapt to various internal and external automatic lines, improving machining efficiency

Parameters

Working Range

Unit

- Max. Swing Over Bed

- Φ400mm

- Max.Turning Length

- 300mm

- Max.Turning Dia

- Φ320mm

- Max. Swing Over Carriage

- Φ160mm

- X/Z Axis Travel

- 460/365mm

Spindle

Unit

- Spindle Hole Taper

- A2-5

- Max. Passing Bar Dia.

- Φ42mm

- Spindle Speed Range

- 50-5000rpm

- Power

- 7.5/11kW

- Standard Chuck Dia.

- Φ42Collet

Feed

Unit

- Rapid Feed Rate

- 20/24m/min

Tailstock

Unit

- Tailstock Spindle Taper

- /

Turret

Unit

- Standard Turret

- Gang Tool/Driven Head

- Nearby Tool Select

- /

Machine

Unit

- Machine Dimension

- 2200*1600*1700mm

- Machine Weight

- 2500kg